- Home Page

- Company Profile

-

Our Products

- Measuring Instrument

- 3 Bricks Granite Polishing Head

- Insize Caliper

- Digital Micrometer

- Miranda Products

- HSS And TCT Annular Cutter

- Tungsten Carbide Tipped Tools

- Center Drills

- HSS Jobber Drill Sets

- High Performance Platinum Cut Taps

- HSS Jobber Drills

- HSS Stub Series Drills

- Standard Series HSS Parallel Shank Endmills

- Reinforced Shank Hand And Short Machine Taps

- HSS Long Series Drills

- High Performance Ball Nose Carbide

- Solid Carbide Jobber Drill

- Gold Long Drills

- Regular Series HSS Taper Shank Drills

- Long Series HSS Taper Shank Twist Drills

- Ball Shape Tungsten Carbide Rotary Burrs

- Cutting Tools

- 65 HRC Solid Carbide End Mill

- Dormer Precision HSS-E AIRCRAFT EXTENSION DRILL 6-12

- Quick Change Drill Chuck

- KTA Quick Change Drilling & Tapping CHuck

- Nine9 Chamfering Cutter 45 Degree Dia 10, 16, 25

- PCD Tools for Non Ferrous material

- Carbide T Slot Cutter

- DORMER Hydra Drill Heads

- Drill Chuck Key

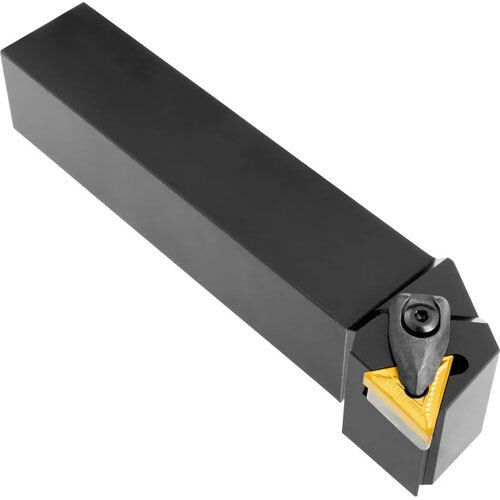

- Carbide Tipped Tools

- Drill Chuck

- HSS Cutting Tools

- Mini Drill Chuck

- Nine9 Engraving Cutter With Insert 30 45 60 90 Degree

- Turning Inserts

- CNC Solid Carbide Tools

- Modular Indexable Head (Cartidge) KHP-lBNR-L

- Tungsten Carbide Burr

- PRAMET CNC Carbide Inserts

- MIRANDA Make Tungsten Carbide Rotary Burr

- Metal Cutting Tools

- Solid Hss End Mills

- Solid Hss End Mills

- HSCO Centre Drill Bits

- Finetech Boring Kit Rough-Finish Boring Bar MBK 10-135

- Threading Tap

- Turning Holder

- Cnc Tools

- DORMER HSCO PFX Drill Coated-Uncoated

- Deburring Blades

- Carbide Concrete Drilling Bits

- Solid Carbide Drills

- 303DA Carbide Drill 3xD

- Auger Carbide Bullet

- Concrete Drill Bit

- Hole Making Solid Carbide Step Drills

- Square Carbide Insert SNGX 110416SR

- Carbide Tools

- Deep Hole Drilling BTA Drill Head & Inserts

- High Feed Cutter Sngx 8 Cutting Edge

- Indexable Carbide Inserts

- Drill Machine Chuck

- Baby Collet Chuck

- Keyless Drill Chuck

- ER 11 Collet

- D Clamp Top External Turning Tool

- External Turning Tool

- Turret Sleeve for CNC Turning

- 65 HRC SS Ball Nose Cutter

- PRAMET Milling Inserts HNGX 0906ANSN

- Bar Peeling Carbide Inserts

- Carbide Milling Insert

- CNC Power Chucks

- KTA Die Mould Chuck

- Carbide Rotary Burrs

- PRAMET GL Deep Grooving Block & Blade

- PRAMET U Drill 2xD 3xD, 5xD with 4 Corner Square Insert

- Tube Scarfing Insert SNMX 19-R50 6640

- Tube Scarfing Insert SNMX 19-R50 6640

- Solid Carbide Reamers

- Polycrystalline Diamond PCD Inserts

- DORMER Make HSS Drill cum Tap Combo

- Nine9 Chamfering Cutter 45 Degree Dia 10, 16, 25 N9MT

- Nine9 Engraving Cutter With Insert 30 45 60 90 Degree V9MT, V045, V060

- DORMER HSS Tool Bits

- DORMER HSS Reamer

- DORMER HSS Hand Taps M, MF, UNC, UNF, UN, BSW, BSF, BSP, NPT, Helicoil

- DORMER HSS-E PM Taps E003Mxx and EX01Mxx

- PVD Coating on HSS-Carbide Tools TiN, TiAlN, AlCroNa, TiSiN, NanoBlue etc

- Air Impact Wrench

- DORMER Countersink HSS-Carbide G400-G335-G600-G132-G138

- DORMER HSS Centre Drill - Cut Centre

- Drill Bit Set

- PRAMET Indexable Ballnose cutter - Banana cutter

- Nine Make Indexable Centre Drill I Centre

- DORMER HSS Drill Sets A022, A095, A188, A190, A295

- DORMER HSS-E Square Tool Bits

- Resharpening of HSS & Carbide Tools

- HCHCR Precision Tool

- Electric Die Grinder

- Hss Cutting Tools

- Hss Tool Bits

- HSS Slotting Cutter

- Tool Bits

- NOGA Deburring Kit

- HSCo Centre Drill Bit

- Cutting Tools

- Nine Corner Rounding Tools N9MT 11T3CTRC20

- Cutting Tools

- DORMER HSS-E PFX Drills A920, A900, A940, A976, A976

- DORMER Carbide Reamer

- DORMER HSCo Centre Drill Bit

- HSS Spiral Flute Taps

- DORMER HSS Conical Drill

- DORMER HSCO PFX Drill Coated-Uncoated

- Milling Cutters

- Revolving Center

- Turret Sleeve

- Boring Bar

- Collet Adapter

- Carbide Bush

- Clamping Kit

- Nine Products

- Clamping Fixture

- Bench Vice

- Machine Vice

- Dormer Products

- Carbide Inserts

- Magnetic Block

- Milling Tools

- Pramet Products

- KTA Products

- Nicon Products

- NICON Make Hydraulic Machine Vice

- NICON Angle Plate Cast Iron Slotted

- Machine Vice

- Compact Lock Down Jaw Machine Vice

- NICON 3 Way Tilting & Swivel Machine Vice

- Lock Down Jaw Machine Vice

- Hydraulic Machine Vice

- NICON 2 Way Tilting & Swivel Vice

- Nicon 2 Piece Precision Modular Vice

- NICON Polygon Rising Block for 5 Axis Vice

- Nicon Compact Lock Down Jaw Machine Vice

- NICON Rising Block for 5 Axis Vice

- Nicon Self Centering Shaft Vice 40-150 mm

- NICON Compact High Grip Machine Vice

- NICON Make Multi Grip Vice Hardened Steel

- Modular Precision Vice

- PRAMET Milling Inserts HNGX 0906ANSN

- NICON Make Tool Maker Grinding Vice Pin & Screw Type TMV & TMVP

- NICON Heavy Duty Bench Vice Cross Rib - Double Rib type

- NICON Precision Drill Vice Unbreakable Alloy Steel

- NICON Self Centering Shaft Vice 100 mm

- NICON Compact Universal Vice for Tool & Cutter Grinder

- Vertex Fostex Hydraulic Machine Vise

- Drill Chuck

- Sine Vice

- Universal Vice

- V Block

- Tool Holder

- Machine Tools Accessories

- Machine Tools Accessories

- Self Centering Vice

- Nicon Lock Down Jaw Machine Vice

- NICON Adjustable Angle Plate

- TURNMAX Revolving Centre Heavy Duty R Model with Interchangeable Point MT2, MT3, MT4, MT5, MT6

- Turnmax Revolving Center CNC High Speed R Model MT2 to MT6

- NICON Self Centering Compact High Grip Machine Vice

- Granite Surface Plates

- Bench Center 1000mm

- Cast Iron Surface Plates

- Insize Digital Vernier Caliper

- Vertex Hydraulic Machine Vise

- NICON Make Tool Maker Sine Grinding Vice

- Tilting Table

- Precision Machined Components

- Wedge Clamp

- Milling Machine Accessories

- Chuck Jaws

- Collet Chuck

- Tool Trolley

- Contact Us

Tungsten Carbide Scrap

1700 INR/Kilograms

Product Details:

- Type Construction Tool Parts

- Material Carbide

- Size Standard

- Product Type Tungsten Carbide Scrap

- Color Grey

- Dimensions Standard

- Weight Varies

- Click to view more

X

Tungsten Carbide Scrap Price And Quantity

- 10 Piece

- 1700 INR/Kilograms

- Approximately 14.5 - 15.1 g/cm³

- Typically 88-96% tungsten content

- Extremely hard (Mohs >9)

- Recycled/used tool parts and bits

- Recycling, tool manufacturing, alloy making

Tungsten Carbide Scrap Product Specifications

- Varies

- Construction Tool Parts

- Grey

- Standard

- Standard

- Carbide

- Tungsten Carbide Scrap

- Approximately 14.5 - 15.1 g/cm³

- Typically 88-96% tungsten content

- Extremely hard (Mohs >9)

- Recycled/used tool parts and bits

- Recycling, tool manufacturing, alloy making

Tungsten Carbide Scrap Trade Information

- 1000 Piece Per Month

- 7 Days

Product Description

Spotlight on our New Tungsten Carbide Scrap-a Paragon of durability, revered for its Outstanding quality and monumental value in the recycling and tooling sectors. With a remarkable purity of 88-96% tungsten content, this grey carbide material, predominantly sourced from recycled/used tool parts and bits, delivers substantial density (14.5-15.1 g/cm3) and extreme hardness (Mohs >9). Ideal for alloy making, tool manufacturing, and industrial recycling, these standard-sized scrap parts offer both reliability and a significant Discount for bulk buyers. Supplied by a top-tier dealer, exporter, and wholesaler from India.

Key Applications and Uses of Tungsten Carbide Scrap

Tungsten Carbide Scrap is highly valued for its use in diverse environments. It serves specific purposes in the recycling industry, where it is a critical resource for creating new alloys and manufacturing cutting-edge tools. Its outstanding hardness makes it ideal for demanding commercial applications, particularly in construction and metalworking. This monumental material finds a predominant role in industries focused on tool production, refurbishment, and heavy-duty machinery, contributing to efficient, sustainable manufacturing processes.

FOB Port, Main Domestic Market, and Packaging Details

Typically traded through major Indian ports under FOB terms, Tungsten Carbide Scrap is available for prompt Estimate and Purchase Order arrangements. The main domestic markets include industrial hubs nationwide, ensuring efficient and wide-ranging coverage. Packaging details adhere to export-grade standards with secure, heavy-duty containers to prevent loss or contamination. Whether for local use or international export, we tailor logistics solutions to meet every need, enhancing client convenience and satisfaction with each transaction.

Key Applications and Uses of Tungsten Carbide Scrap

Tungsten Carbide Scrap is highly valued for its use in diverse environments. It serves specific purposes in the recycling industry, where it is a critical resource for creating new alloys and manufacturing cutting-edge tools. Its outstanding hardness makes it ideal for demanding commercial applications, particularly in construction and metalworking. This monumental material finds a predominant role in industries focused on tool production, refurbishment, and heavy-duty machinery, contributing to efficient, sustainable manufacturing processes.

FOB Port, Main Domestic Market, and Packaging Details

Typically traded through major Indian ports under FOB terms, Tungsten Carbide Scrap is available for prompt Estimate and Purchase Order arrangements. The main domestic markets include industrial hubs nationwide, ensuring efficient and wide-ranging coverage. Packaging details adhere to export-grade standards with secure, heavy-duty containers to prevent loss or contamination. Whether for local use or international export, we tailor logistics solutions to meet every need, enhancing client convenience and satisfaction with each transaction.

FAQ's of Tungsten Carbide Scrap:

Q: How is tungsten carbide scrap typically used in industrial applications?

A: Tungsten carbide scrap is primarily used for recycling into new alloys and for manufacturing industrial tools such as cutting bits, drills, and wear-resistant machinery components.Q: What is the process for sourcing and supplying this tungsten carbide scrap?

A: We source our tungsten carbide scrap from recycled or used tool parts, then systematically sort and prepare them to guarantee optimal purity before supplying to manufacturers and recyclers.Q: Where can buyers place a purchase order for Tungsten Carbide Scrap?

A: Buyers can place a purchase order directly through our sales office, via our website, or through authorized exporters and suppliers across India.Q: When should companies consider using tungsten carbide scrap?

A: Companies should consider using tungsten carbide scrap when looking to reduce costs, support sustainable manufacturing, or when alloy remanufacturing is required for tool production.Q: What are the benefits of using tungsten carbide scrap for recycling purposes?

A: Utilizing tungsten carbide scrap provides cost savings, reduces environmental impact, and contributes to a circular economy by maximizing resource efficiency in industrial manufacturing.Q: How is the product packaged for safer transport and delivery in domestic and international markets?

A: The scrap is securely packed in heavy-duty containers, carefully sealed to avoid contamination or material loss, conforming to both domestic and export packaging standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email