- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- उपकरण को मापना

- मिरांडा उत्पाद

- HSS और TCT एन्युलर कटर

- टंगस्टन कार्बाइड टिप्ड टूल्स

- सेंटर ड्रिल्स

- HSS जॉबर ड्रिल सेट

- हाई परफॉरमेंस प्लेटिनम कट टैप्स

- HSS जॉबर ड्रिल

- HSS स्टब सीरीज़ ड्रिल

- स्टैंडर्ड सीरीज़ HSS पैरेलल शंक एंडमिल्स

- प्रबलित शैंक हैंड एंड शॉर्ट मशीन टैप्स

- HSS लॉन्ग सीरीज़ ड्रिल

- हाई परफॉरमेंस बॉल नोज कार्बाइड

- सॉलिड कार्बाइड जॉबर ड्रिल

- गोल्ड लॉन्ग ड्रिल्स

- रेगुलर सीरीज़ HSS टेपर शैंक ड्रिल

- लॉन्ग सीरीज़ HSS टेपर शैंक ट्विस्ट ड्रिल

- बॉल शेप टंगस्टन कार्बाइड रोटरी बर्स

- काटने के उपकरण

- 65 HRC सॉलिड कार्बाइड एंड मिल

- डॉर्मर प्रिसिजन एचएसएस-ई एयरक्राफ्ट एक्सटेंशन ड्रिल 6-12

- क्विक चेंज ड्रिल चक

- KTA क्विक चेंज ड्रिलिंग और टैपिंग चक

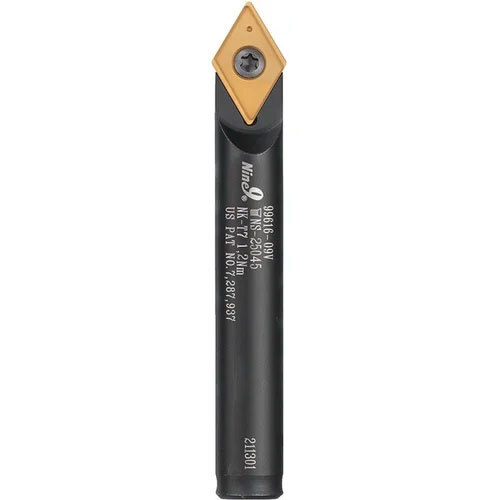

- नाइन 9 चम्फरिंग कटर 45 डिग्री दीया 10, 16, 25

- गैर लौह सामग्री के लिए PCD उपकरण

- कार्बाइड टी स्लॉट कटर

- डॉर्मर हाइड्रा ड्रिल हेड्स

- ड्रिल चक कुंजी

- कार्बाइड टिप्ड टूल्स

- ड्रिल चक

- HSS कटिंग टूल्स

- मिनी ड्रिल चक

- 30 45 60 90 डिग्री इन्सर्ट के साथ नाइन 9 एनग्रेविंग कटर

- टर्निंग इंसर्ट

- सीएनसी सॉलिड कार्बाइड टूल्स

- मॉड्यूलर इंडेक्सेबल हेड (कार्टिज) KHP-LBNR-L

- टंगस्टन कार्बाइड बर

- PRAMET सीएनसी कार्बाइड इंसर्ट

- मिरांडा टंगस्टन कार्बाइड रोटरी बर बनाते हैं

- धातु काटने के उपकरण

- सॉलिड एचएसएस एंड मिल्स

- सॉलिड एचएसएस एंड मिल्स

- HSCO सेंटर ड्रिल बिट्स

- फिनटेक बोरिंग किट रफ-फिनिश बोरिंग बार MBK 10-135

- थ्रेडिंग टैप

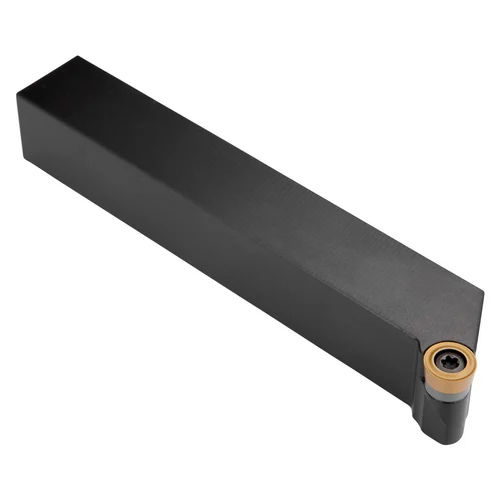

- टर्निंग होल्डर

- सीएनसी टूल्स

- DORMER HSCO PFX ड्रिल कोटेड-अनकोटेड

- डिबुरिंग ब्लेड्स

- कार्बाइड कंक्रीट ड्रिलिंग बिट्स

- सॉलिड कार्बाइड ड्रिल

- 303DA कार्बाइड ड्रिल 3xD

- ऑगर कार्बाइड बुलेट

- कंक्रीट ड्रिल बिट

- होल मेकिंग सॉलिड कार्बाइड स्टेप ड्रिल

- स्क्वायर कार्बाइड इन्सर्ट SNGX 110416SR

- कार्बाइड टूल्स

- डीप होल ड्रिलिंग BTA ड्रिल हेड एंड इंसर्ट

- हाई फीड कटर Sngx 8 कटिंग एज

- इंडेक्सेबल कार्बाइड इंसर्ट

- ड्रिल मशीन चक

- बेबी कोलेट चक

- कीलेस ड्रिल चक

- ईआर 11 कोलेट

- डी क्लैंप टॉप एक्सटर्नल टर्निंग टूल

- एक्सटर्नल टर्निंग टूल

- सीएनसी टर्निंग के लिए बुर्ज स्लीव

- 65 HRC SS बॉल नोज कटर

- PRAMET मिलिंग इंसर्ट HNGX 0906ANSN

- बार पीलिंग कार्बाइड इंसर्ट

- कार्बाइड मिलिंग इंसर्ट

- सीएनसी पावर चक्स

- KTA डाई मोल्ड चक

- कार्बाइड रोटरी बर्स

- PRAMET GL डीप ग्रूविंग ब्लॉक एंड ब्लेड

- PRAMET U ड्रिल 2xD 3xD, 5xD 4 कॉर्नर स्क्वायर इन्सर्ट के साथ

- ट्यूब स्कार्फिंग इन्सर्ट SNMX 19-R50 6640

- ट्यूब स्कार्फिंग इन्सर्ट SNMX 19-R50 6640

- सॉलिड कार्बाइड रीमर्स

- पॉलीक्रिस्टलाइन डायमंड पीसीडी इंसर्ट

- एचएसएस काटने के उपकरण

- मिलिंग कटर

- घूमने वाला केंद्र

- बुर्ज आस्तीन

- ऊबाउ बार

- कोलेट एडाप्टर

- कार्बाइड बुश

- क्लैंपिंग किट

- नौ उत्पाद

- क्लैम्पिंग फिक्स्चर

- डॉर्मर उत्पाद

- प्रामेट उत्पाद

- केटीए उत्पाद

- परिशुद्धता मशीन वाइस

- निकॉन एंगल प्लेट कास्ट आयरन स्लॉटेड

- NICON मेक हाइड्रोलिक मशीन वाइस

- मिलिंग मशीन वाइस

- कॉम्पैक्ट लॉक डाउन जॉ मशीन वाइस

- लॉक डाउन जॉ मशीन वाइस

- NICON 3 वे टिल्टिंग एंड स्विवेल मशीन वाइस

- हाइड्रोलिक मशीन वाइस

- निकॉन 2 वे टिल्टिंग एंड स्विवेल वाइस

- निकॉन 2 पीस प्रिसिजन मॉड्यूलर वाइस

- 5 एक्सिस वाइस के लिए निकॉन पॉलीगॉन राइजिंग ब्लॉक

- निकॉन कॉम्पैक्ट लॉक डाउन जॉ मशीन वाइस

- 5 एक्सिस वाइस के लिए NICON राइजिंग ब्लॉक

- निकॉन सेल्फ सेंटरिंग शाफ्ट वाइस 40-150 मिमी

- NICON कॉम्पैक्ट हाई ग्रिप मशीन वाइस

- NICON मेक मल्टी ग्रिप वाइस हार्डन स्टील

- मॉड्यूलर प्रिसिजन मशीन वाइस

- PRAMET मिलिंग इंसर्ट HNGX 0906ANSN

- NICON मेक टूल मेकर ग्राइंडिंग वाइस पिन और स्क्रू टाइप TMV & TMVP

- NICON हैवी ड्यूटी बेंच वाइस क्रॉस रिब - डबल रिब टाइप

- निकॉन प्रिसिजन ड्रिल वाइस अनब्रेकेबल अलॉय स्टील

- निकॉन सेल्फ सेंटरिंग शाफ्ट वाइस 100 मिमी

- टूल एंड कटर ग्राइंडर के लिए NICON कॉम्पैक्ट यूनिवर्सल वाइस

- वर्टेक्स फॉस्टेक्स हाइड्रोलिक मशीन वाइस

- औज़ार धारक

- मशीन टूल्स सहायक उपकरण

- झुकाने वाली मेज

- परिशुद्ध मशीनीकृत घटक

- वेज क्लैंप

- चक जबड़े

- टूल ट्रॉली

- संपर्क करें

Nine9 Engraving Cutter With Insert 30 45 60 90 Degree V9MT, V045, V060

5150 आईएनआर/टुकड़ा

उत्पाद विवरण:

- ऑपरेशन का प्रकार

- लेप करना TiN (Titanium Nitride) or Uncoated (According to insert type)

- कटिंग स्पीड Recommended: 80-180 m/min (varies by material)

- मशीन का प्रकार CNC Milling, Conventional Milling

- कोटिंग का प्रकार PVD or CVD (varies by insert selection)

- विशेषताएँ Replaceable insert, multi-angle tool, precision machining, high durability

- शेप V-Type (30°, 45°, 60°, 90°)

- Click to view more

X

मूल्य और मात्रा

- 10

उत्पाद की विशेषताएं

- Standard (Model-dependent)

- Standard

- Suitable for fine detailed engraving, marking, and chamfering

- Industrial

- Nine9 Engraving Cutter With Insert 30 45 60 90 Degree V9MT, V045, V060

- Black

- Optimized for low cutting resistance

- Not Applicable (Engraving Cutter)

- High Precision ±0.01 mm

- V-Type (30°, 45°, 60°, 90°)

- CNC or conventional milling machine

- Engraving Cutter with Insert

- HRC 60-63 (for insert)

- V-groove Engraving Cutter

- Engraving, Chamfering, Marking

- Replaceable insert, multi-angle tool, precision machining, high durability

- Standard (Refer to model-specific chart)

- TiN (Titanium Nitride) or Uncoated (According to insert type)

- Recommended: 80-180 m/min (varies by material)

- PVD or CVD (varies by insert selection)

- CNC Milling, Conventional Milling

- Designed for high-torque industrial use

व्यापार सूचना

- प्रति महीने

- दिन

उत्पाद विवरण

Experience the incomparable precision of the Nine9 Engraving Cutter With Insert (30, 45, 60, 90 Degree: V9MT, V045, V060)crafted for optimum efficiency and perfect results. With replaceable carbide inserts, this cutter delivers fresh, sharp performance every use. Its multi-angle versatility suits engraving, V-cutting, chamfering, and marking on a variety of materials including metals and plastics. Shop now for a limited time and enjoy high-speed, high-precision machining compatible with CNC and conventional milling machines. TiN coating ensures durability, while high accuracy (0.01 mm) guarantees superior detailing for industrial applications.

Versatile Industrial Application & Usage

The Nine9 Engraving Cutter (V9MT, V045, V060) is engineered for industrial usage such as engraving, V-cutting, chamfering, and marking. Its interchangeable inserts allow usage across various angles, making it perfect for detailed work on metal, plastic, or non-ferrous materials. Commercially, its suitable for machining centers, CNC lathes, and milling machines. This cutter excels in high-speed cutting operations and is ideal for both production and prototyping environments requiring sharp and precise outputs.

Export Markets, Valuation & Order Processing

Nine9 Engraving Cutters are supplied globally with key export markets in India and beyond. The product is competitively valued for dealers, exporters, and wholesalers. Payment terms range from advance transfers to credit arrangements, ensuring smooth transactions. Our streamlined order processing guarantees prompt delivery times, making us a reliable partner for industrial buyers. Supply consistency and dependability remain our priority, ensuring cutters reach clients efficiently and in optimum condition.

Versatile Industrial Application & Usage

The Nine9 Engraving Cutter (V9MT, V045, V060) is engineered for industrial usage such as engraving, V-cutting, chamfering, and marking. Its interchangeable inserts allow usage across various angles, making it perfect for detailed work on metal, plastic, or non-ferrous materials. Commercially, its suitable for machining centers, CNC lathes, and milling machines. This cutter excels in high-speed cutting operations and is ideal for both production and prototyping environments requiring sharp and precise outputs.

Export Markets, Valuation & Order Processing

Nine9 Engraving Cutters are supplied globally with key export markets in India and beyond. The product is competitively valued for dealers, exporters, and wholesalers. Payment terms range from advance transfers to credit arrangements, ensuring smooth transactions. Our streamlined order processing guarantees prompt delivery times, making us a reliable partner for industrial buyers. Supply consistency and dependability remain our priority, ensuring cutters reach clients efficiently and in optimum condition.

FAQs of Nine9 Engraving Cutter With Insert 30 45 60 90 Degree V9MT, V045, V060:

Q: How do I select the appropriate insert angle for different engraving tasks?

A: Choose the insert angle (30, 45, 60, or 90) based on the depth, profile, and style of your engraving or marking requirements. Each insert offers specific cutting characteristics ideal for different applications.Q: What materials can the Nine9 Engraving Cutter process?

A: This cutter is suitable for processing metal, plastic, and non-ferrous materials. It works efficiently in both CNC and conventional milling setups.Q: When should I replace the insert to maintain optimum cutting performance?

A: Replace the insert whenever you notice dull edges, increased cutting resistance, or reduced precision. Regular replacement ensures fresh, sharp performance and keeps operations efficient.Q: Where can I order and receive supply of Nine9 Engraving Cutters?

A: You can place orders through authorized dealers, exporters, suppliers, and wholesalers in India and internationally. Efficient order processing enables quick delivery to your location.Q: What is the benefit of the TiN coating or uncoated options for inserts?

A: TiN coating enhances durability and wear resistance. Depending on the material and process requirement, you can choose coated or uncoated inserts to optimize tool life and machining quality.Q: How does the high-precision accuracy benefit industrial usage?

A: With cutting accuracy of 0.01 mm, the Nine9 Engraving Cutter achieves sharp, detailed engravings and chamfers, ideal for applications demanding superior precision in industrial settings.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email